Container foil and surface oil treatment

2017/2/25 9:27:45

For the preparation of various containers of pre-coated aluminum foil, commonly used alloy 8011,3003,3004,1145, etc., the thickness of 0.02-0.08mm. Oil thickness 150-400mg / m².

With the continuous development of the national economy and the continuous improvement of people's living standards, people's health awareness has been strengthened, as well as people's awareness of environmental protection, half of the use of aluminum foil as a semi-rigid container to eat food at home and abroad has been widely used Rigid container aluminum foil gradually replaced the traditional foam, plastic food box.

Semi-rigid container foil is generally made of single-piece foil, and in order to make a variety of shape containers, need to use the way to foil aluminum foil stamping. But in the absence of any treatment of aluminum foil in the case of stamping in the process, due to friction caused by aluminum foil scratches and reduce the quality of products. Therefore, the aluminum foil before the surface of the oil coating, due to the oil lubrication effect to protect the aluminum foil surface is not affected, improve product quality.

The traditional way of oiling to roll the main way, roller coating is the most primitive way of oiling, the use of roller coating method of aluminum foil surface oil often caused by aluminum foil surface with uneven oil, and make the production process in the stamping process is not smooth. With less oil lubrication effect is not obvious, aluminum foil will be scratched; with more oil will make aluminum foil and stamping parts and other problems.

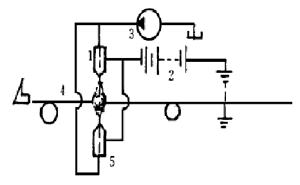

By rolling steel industry on the strip surface rust-proof treatment of inspiration, people began to use electrostatic spraying on the aluminum foil surface spray treatment. Whether it is imported electrostatic paint machine or domestic electrostatic oiling machine, the effect is significantly better than the traditional roller-type oiling machine is much better, not only oil evenly, and save oil, by the customer's many praise. Electrostatic oil painting machine oil as shown in the diagram.

Electrostatic oiling schematic

Can be seen from the injection of oil from the edge of the oil after the changes in the form, can be divided into oil, atomization, oiling three stages. From the edge of the fuel injection beam 1 when the oil is relatively thick sparse with a negative oil droplets. In the same role of mutual repulsion of the charge, the oil droplets from the edge of a certain distance will be scattered into small particles, the farther away from the edge of the smaller grain, the number becomes more, the oil gradually fog, shape Such as fuel injection "fuel injection". With negative electric particles along the electric field in the electric field to the aluminum foil surface fast movement, numerous dense small oil particles eventually adsorbed on the surface of the aluminum foil to achieve the classic oil.