Development of high - gloss cardboard with double - zero aluminum foil production process£®1£©

2017/3/29 9:36:04

Because double-zero aluminum foil has the advantages of good formability, beautiful surface, light weight, corrosion resistance and high strength, it is widely used in tobacco and food packaging. And tobacco and food and other packaging is cardboard with double zero foil as a consumable, the market demand is higher, gloss is the quality of paper with double zero foil is an important indicator. Packaging enterprises use aluminum foil according to user requirements bright, dark surface are required to use, by adjusting the roll surface roughness and rolling oil index to improve the double zero foil surface gloss. Hot-rolled billet production of double-zero foil surface is more fine than the casting billet, so the test using hot-rolled billet.

Production Process

Pass assignments

Foil rolling each sub-control reasonable reasonable processing rate in order to ensure the follow-up rolling smoothly, rolling parameters are balanced, can get a better aluminum foil surface, plate shape. According to the characteristics of hot-rolled billet, pass the following allocation (unit: mm):

Scenario 1: 0.28-0.115-0.043-0.0150-0.0060x2

Option 2: 0.28-0.175-0.080-0.034-0.0148-0.0060x2

Intermediate annealing

Hot-rolled billet is different from the casting billet, the production to the finished product before the double-pass, due to high degree of work hardening caused by high tensile strength, resulting in double-joint sub-surface quality is poor, easy to break and pinhole Many, the need for low-temperature annealing to produce deformation of the deformation of the organization. The process is as follows:

0.0148-0.0150mm One-way coiling machine Low-temperature annealing - rolled to 0.0060mmX2

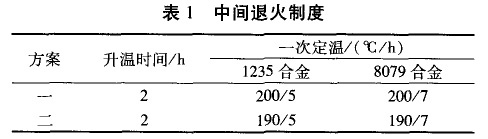

The intermediate annealing system is shown in Table 1.