Development plan and test result of double - zero aluminum foil for high gloss cardboard

2017/4/10 14:23:05

Processing pass

The program is a reduction of production due to the higher processing rate, the plate is not easy to control and prone to Ma skin defects, in the loose loose, tight side of the two ribs; program two processing rate of small plate more flat. So choose option two.

Intermediate annealing

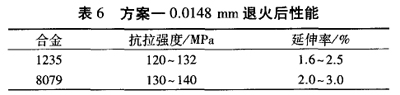

(1) After the program an intermediate annealing performance in Table 6.

After annealing, the tensile strength is low, resulting in lower finished product rolling speed.

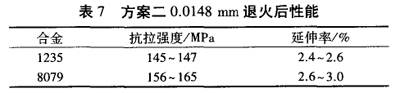

(2) After the two intermediate annealing performance in Table 7.

After annealing, the tensile strength conforms to the requirements of the next pass, the surface quality is better and the pinholes are reduced.

Roll grinding

(1) support roller selection program one or two surface quality can meet the requirements, but the use of the program grinding time is longer, so the use of program two.

(2) work roll selection program One, two, three finished dark side and bright surface quality can meet the requirements. But the program one, two production one, two, three times the pace of slow, four times when the production speed is too fast, making the plate is not easy to control, so the use of three programs.

Analysis of test results

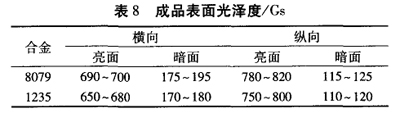

The use of the above process production of cardboard with double zero foil using MN universal gloss meter to measure the dark side and bright gloss see Table 8.

From the table can be seen 8079 alloy surface gloss higher than 1235 alloy, the actual visual inspection 8079 alloy surface than 1235 alloy delicate. After the user uses the surface gloss to meet the requirements. After the development of the product has been put into normal production.