Study on Burning Cause of Operation Bearing Side Bearing of Aluminum Foil Mill

2017/5/17 15:42:49

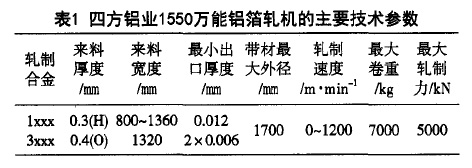

Our company's 260mm / 660mm X1550mm aluminum foil rough rolling mill for the universal aluminum foil mill, designed by the Luoyang Nonferrous Metal Processing Design Institute, the main technical parameters shown in Table 1. In 2005 production, the work roll side bearing with two rows of short cylindrical roll Column bearings (model: 130RV2001 JIS5 / 130 X 200 × 125 NSK) and single row four point contact ball bearings (model: 6024/120 X 180 X 28NSK) configuration, the operation side bearings with two short cylindrical roller bearings (Model: 130RV2001 JIS5 / 130 × 200 × 125NSK) and single row angular contact ball bearings (model: QJ1024MP5 / 120 × 180 X 28 NSK) configuration. In the equipment debugging and rolling process curing process, found that the operating side of the bearing easy to burn, the angular contact ball bearings adjusted to four-point contact ball bearings, work roll bearing life tends to a reasonable range.

Into the 2015, due to market reasons, the equipment started a serious shortage, but frequent occurrence of work roll operation side bearing abnormal burning and premature fatigue damage phenomenon, the rolling body was burned, bearing inner ring and roller diameter adhesion can not be removed and other accidents, On the work of the roller is particularly serious, and sometimes a set of bearings in the actual running time of less than 20 h is scrapped, seriously affected the workshop production. Only 6 - 10 months, there have been 20 times, which led to fire 2 times, seriously affecting production safety. According to the scene statistics, the loss of 20 sets of four-point contact ball bearings, manufacturers have SKF, NSK, HRB, ZWZ and so on. In this paper, only the failure of the four-point contact ball bearing on the working roller is studied.