Analysis and Solution of Burning Measures for Operation Side Bearing of Aluminum Foil Mill£¨1£©

2017/6/7 10:00:22

Reduce axial force

(1) due to the need for roller, the bearing seat and the arch window between the existence of 1-2mm gap, in the open-bound rolling state, the bearing seat vibration is unstable, so that the work roll and support roller axis dynamic Cross, resulting in abnormal axial force and fluctuating axial force components, so that bearing load increases, affecting bearing life. If the use of controlled closed control, both to solve the roll required for the gap with the rolling requirements to eliminate the gap between the contradictions, but also to eliminate the vibration of the bearing seat generated by the dynamic additional load and improve bearing life.

(2) in the bearing seat and four-point contact with the ball bearing contact ring out of the end of the ring out of 3-6 oil tank, so that the oil can enter the bearing inner and roll roller diameter relative rotation of the site, can reduce the bearing inner ring And the relative rotation of the roll heat generated to extend the bearing life.

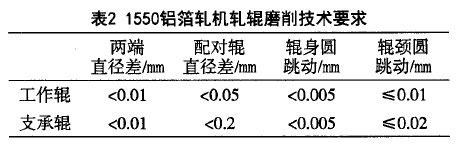

(3) in accordance with the requirements of foil rolling mill grinding grinding technology, matching, elimination due to matching tolerance and round beating tolerance caused by the rotation axis between the roller is not parallel to the axial force, see Table 2.

(4) 1550 aluminum foil mill with the same gear drive, the need to regularly check the gear box gear meshing gap, to prevent gear wear caused by high-speed axial force increases.

(5) The rolling mill is equipped with the PLC roll eccentricity compensation system, which can improve the axial stability of the work roll bearing under certain conditions by correcting the roll seam and increasing the stability of the roller system during rolling mill rolling.